LIVE DEMOS

Experience Innovation in Action!

Discover the latest in textile recycling technology with live demonstrations at the Textiles Recycling Expo! Watch cutting-edge machinery in action as it sorts, processes, and transforms textiles into new materials - bringing circularity to life right before your eyes.

Don't miss this unique opportunity to experience the future of sustainable textiles firsthand!

Mesdan Laboratory Shredding Machine transforms any industrial textile waste (fabrics, yarns, slivers, etc.) and worn-out clothes back into their original fiber forms. The equipment is designed to assist textile manufacturers, institutes and R&D laboratories to evaluate any possibility of mechanical recycling on miniature scale (even with a very low quantity of material) to scale up the production on large scale.

MESDAN, a company of VANDEWIELE (Belgium), is a global leader in yarn joining devices and textile testing equipment.

The MESDAN LAB line—designed, engineered, and manufactured in Italy—offers a comprehensive range of precision instruments for testing fibers, yarns, fabrics (traditional and technical), nonwovens, and leather, ensuring compliance with international standards in both laboratory and production environments.

Recycling & Miniature Spinning MESDAN provides a miniature spinning mill, ideal for research centers, textile institutes, and universities, enabling the production of small yarn batches from short and long staple fibers. Additionally, its miniature shredding machine facilitates lab-scale textile waste recycling, supporting sustainable innovation in the industry.

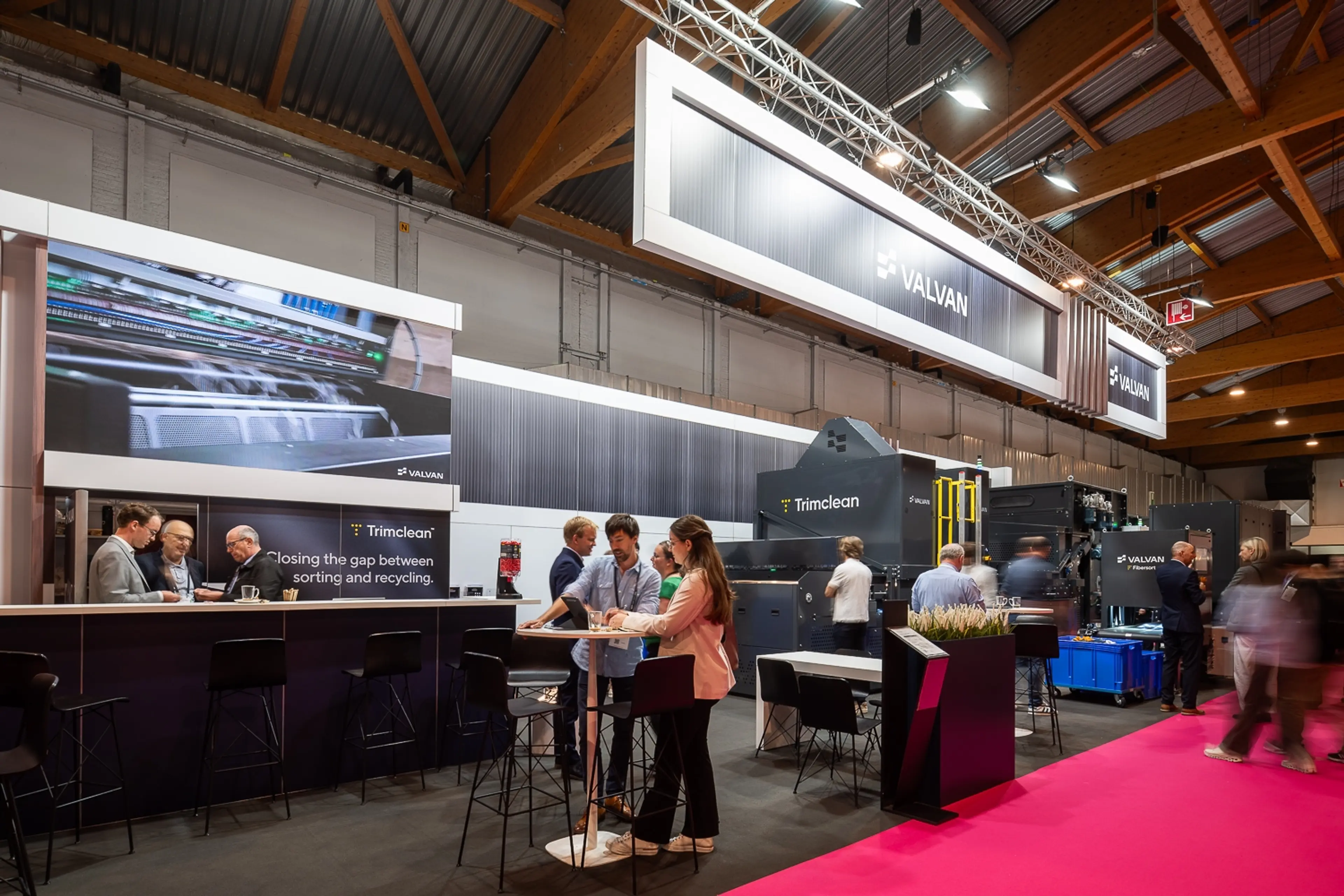

Valvan are showcasing two cutting-edge technologies that are redefining textile sorting and recycling: Fibersort® and Trimclean®.

Fibersort®: This high-tech sorting system uses Near-Infrared Spectroscopy (NIRS) to scan and categorize textiles by fiber composition, color, and structure (woven vs. knitted). With precise virtual labeling, it enables efficient large-scale sorting for recycling.

The garments are introduced into the machinery by the Robotpicker: The dual-arm robotic system feeds textiles into Fibersort® at 32 picks per minute, handling 550–650 kg/hour for seamless processing.

Trimclean®: Taking recycling a step further, this system removes zippers, buttons, labels, and prints using NIR spectrometry, metal sensors, color sorting, and AI-powered detection. By inspecting both sides of the fabric, it ensures high-purity feedstock ready for textile-to-textile recycling.

NewRetex – Advanced AI Sorting for a Circular Textile Future

NewRetex operates one of Europe’s most advanced automated sorting facilities for post-consumer textiles. Located in Denmark, our fully automated AI-powered sorting lines can identify and sort textiles by material composition (30+ fractions), color (any combination), structure, and more — with over 97% purity for clean fractions.

Our sorting lines offer:

- Fully automized sorting with automatic feeding

- High accuracy classification for high purity recyclable fractions

- Conveyor sorting for low energy consumption, noise- and dust-free operation

- Operational capacity of 2.000 picks/hour corresponding to 3.000 tons per year

- Full traceability with our proprietary Manufacturing Execution System, “HUGIN”. Including real-time KPI monitoring and compatibility with the future DPP.

Designed, engineered, and built in Denmark, the NewRetex sorting line is based on proven technologies, ready to scale across Europe in response to upcoming EU textile waste legislation.

We are currently rolling out our unique technologies while creating the most efficient, traceable value chains for circular textiles and other recycled fiber products.

Textechno will showcase textile testing technology that is specifically geared towards the characterization of recycled fibres:

A precise analysis and evaluation of the fibre length distribution is paramount to the mechanical recycling process. This is performed by Textechno’s FIBROTEST. On top, FIBROTEST also measures bundle strength and elongation on colored fibres, fibre blends, synthetic fibres, and natural fibres, making the devices exceptionally suited for all kinds of recycled fibres.

Furthermore, Textechno will bring an MDTA 4 to the show. MDTA 4 separates yarn remnants from mechanically recycled fibres, enabling you to measure the amount of contamination in the recycling material. Also the problematic dusting of recycled fibre is characterized by MDTA4.

Finally, we will also demonstrate CLIF which is Textechno’s system for the Classification of Impurities In Fibres. CLIF identifies, counts and classifies neps and other impurities in recycled fibre material to yield a full view of the mechanical recycling process.